Cracking in asphalt/concrete is a phenomenon that pavement design and maintenance engineers have had to contend with for years. Fatigue cracking is the principal consideration in pavement maintenance. Cracks are inevitable, and neglect leads to accelerated cracking and/or potholing, further reducing pavement life and serviceability.

The problem of cracks is handled in many ways, ranging from pavement maintenance activities, such as surface treatments (seal coating or road slurry and hot rubberized crack sealing) to full-scale pavement rehabilitation projects, such as resurfacing. Maintenance departments/Property management companies bear most of the burden of dealing with cracks. Agencies with sufficient funding are often responsible for adding a few more years of serviceable life to deteriorated pavements, through preventative or routine maintenance, or both.

One of the more common options exercised by city or state maintenance departments is crack sealing. This operation has been conducted for many years, generally on a routine basis. However, only in the last two decades has its potential benefit as a preventive maintenance tool been realized.

Hot applied rubberized crack sealants should not be confused with cold applied Latex crack fillers that are non-elastic. Due to their non-elastic nature, as seasonal temperatures change, causing the asphalt to expand and contract, these cold applied fillers will recrack prematurely causing further asphalt deterioration.

Deteriorization

THE PAVEMENT'S SURFACE TEMPERATURE AT 135° AND ITS BOTTOM TEMPERATURE AT 100° CAUSES PAVEMENT TENSION.

THE PAVEMENT'S SURFACE TEMPERATURE AT 135° AND ITS BOTTOM TEMPERATURE AT 100° CAUSES PAVEMENT TENSION. THE SURFACE OF THE PAVEMENT EXPANDS AND CONTRACTS GREATER THAT THE BOTTOM, CAUSING THE CRACK TO PENETRATE DOWNWARD. (Crack sealant should be applied at this stage)

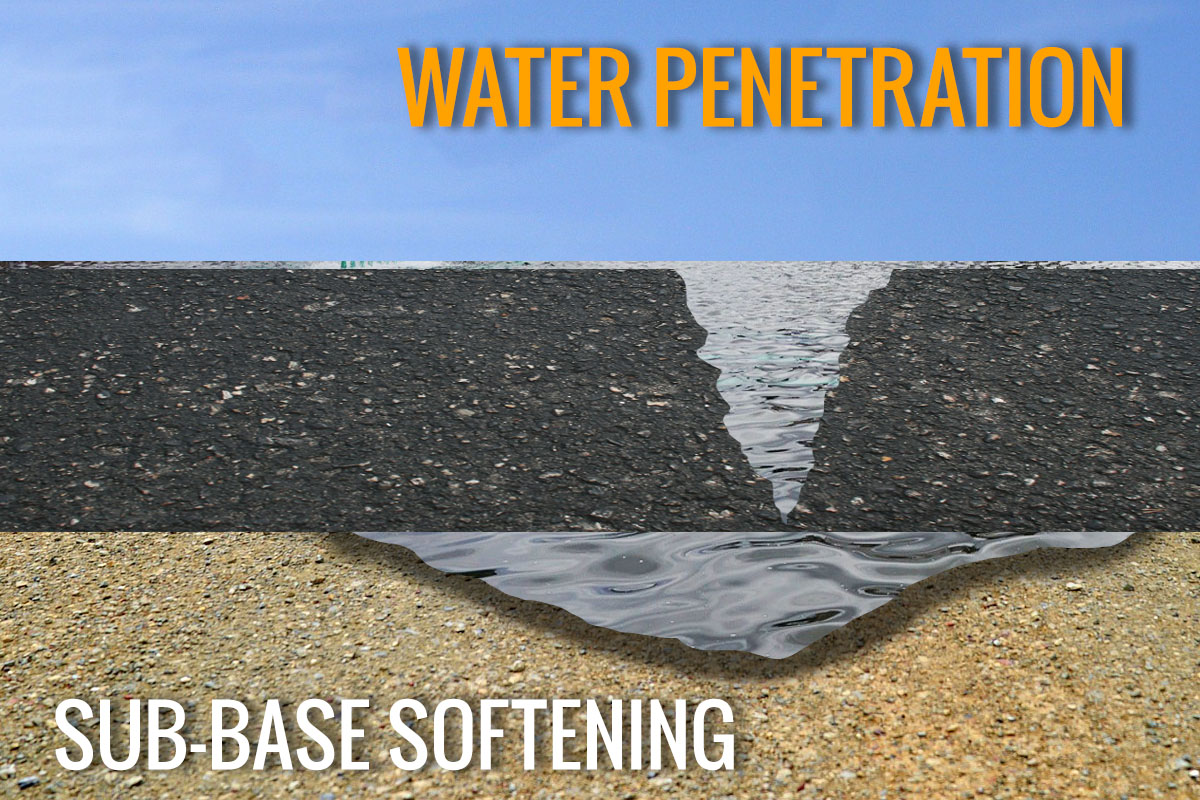

THE SURFACE OF THE PAVEMENT EXPANDS AND CONTRACTS GREATER THAT THE BOTTOM, CAUSING THE CRACK TO PENETRATE DOWNWARD. (Crack sealant should be applied at this stage) IF SEALANT IS NOT APPLIED, WATER PENETRATION OCCURS, THE BASE IS SOFTENED AND THE PAVEMENT LOSES ITS SUPPORT.

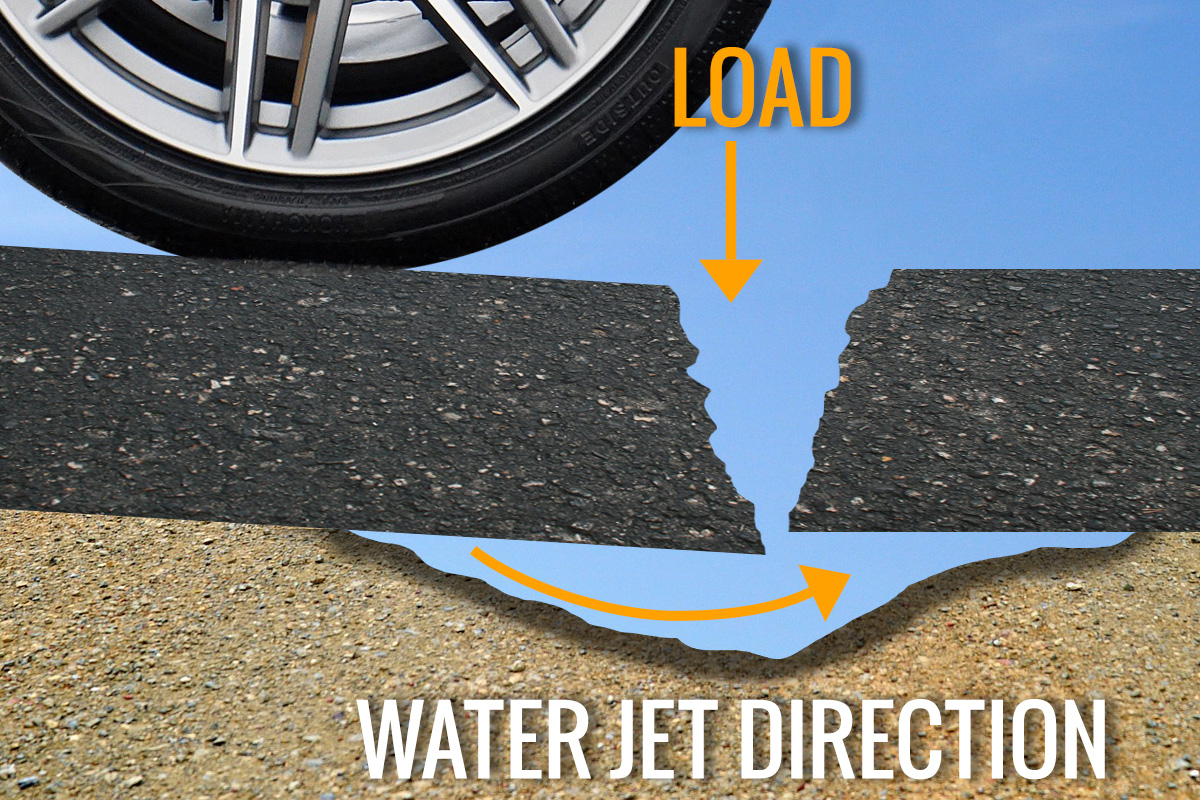

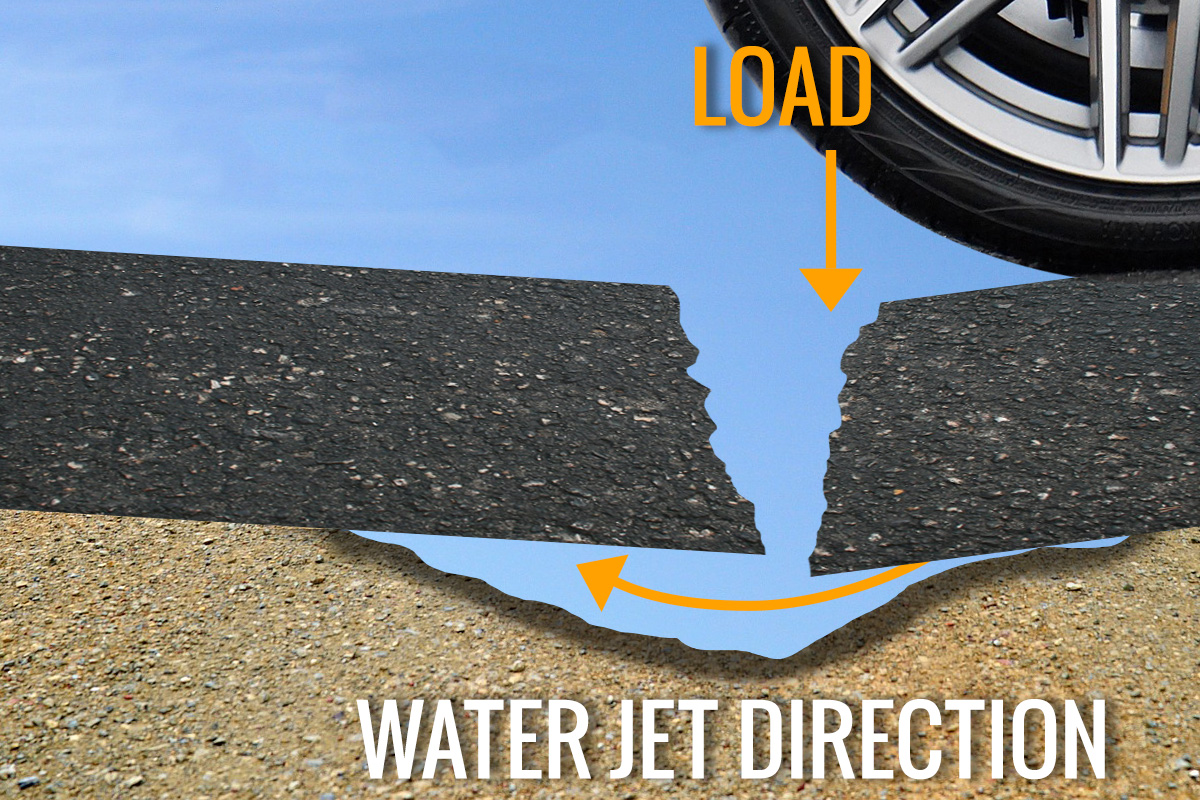

IF SEALANT IS NOT APPLIED, WATER PENETRATION OCCURS, THE BASE IS SOFTENED AND THE PAVEMENT LOSES ITS SUPPORT. VEHICLE LOAD COMPRESSES ASPHALT DOWNWARD CAUSING WATER EROSION TO THE BASE.

VEHICLE LOAD COMPRESSES ASPHALT DOWNWARD CAUSING WATER EROSION TO THE BASE. LOAD CHANGE INCREASES THE EROSION PROCESS.

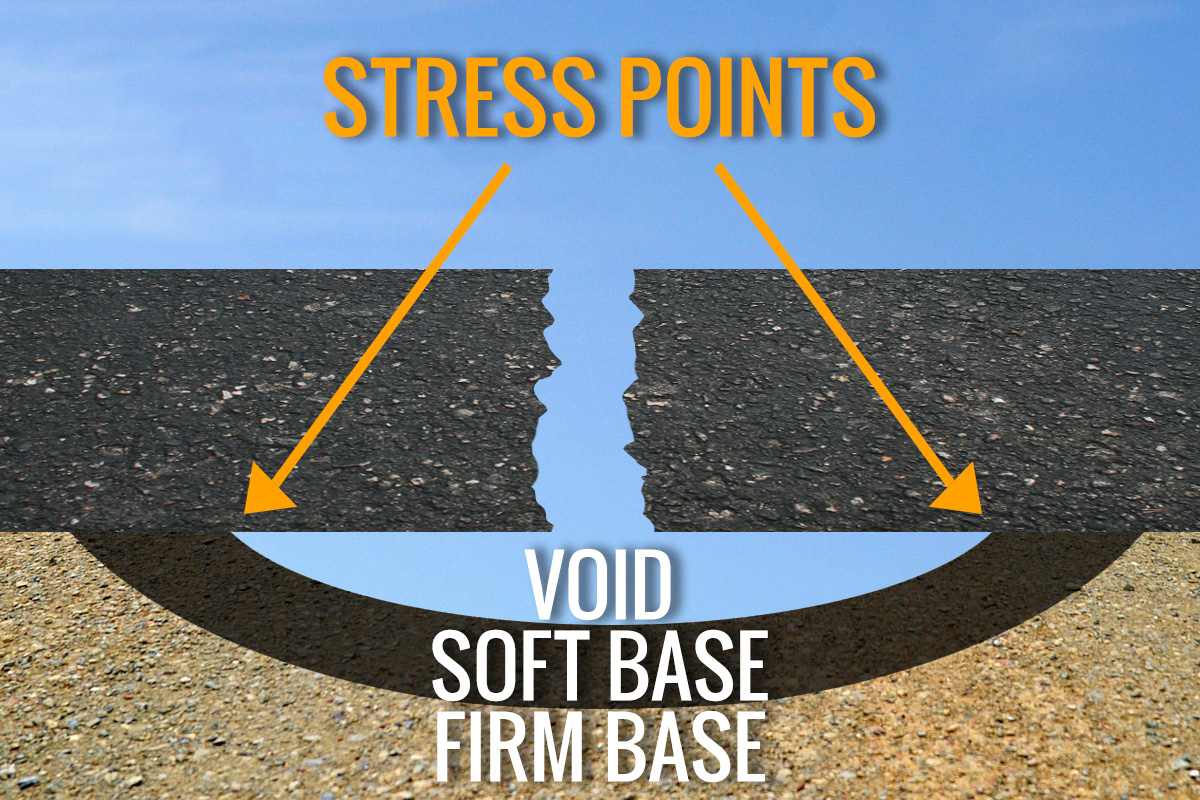

LOAD CHANGE INCREASES THE EROSION PROCESS. EROSION AND WATER EVAPORATION STRIP AWAY SUPPORT FROM UNDERNEATH THE PAVEMENT; THIS CAUSES STRESS POINTS.

EROSION AND WATER EVAPORATION STRIP AWAY SUPPORT FROM UNDERNEATH THE PAVEMENT; THIS CAUSES STRESS POINTS. LOAD BEARING VEHICLES STRESS THE PAVEMENT BEYOND ITS CAPACITY, WHICH CAUSES ASPHALT FAILURE OR "ALLIGATORING".

LOAD BEARING VEHICLES STRESS THE PAVEMENT BEYOND ITS CAPACITY, WHICH CAUSES ASPHALT FAILURE OR "ALLIGATORING". CRACK SEALING SHOULD TAKE PLACE AT STAGE 2, BEFORE WATER PENETRATION CAN OCCUR.

CRACK SEALING SHOULD TAKE PLACE AT STAGE 2, BEFORE WATER PENETRATION CAN OCCUR. ROADWORKS #306 RUBBER SEALANT IS RECOMMENDED FOR CRACKS CAUSED BY THERMAL STRESS.

ROADWORKS #306 RUBBER SEALANT IS RECOMMENDED FOR CRACKS CAUSED BY THERMAL STRESS. ROADWORKS #306 RUBBER SEALANT IS RECOMMENDED FOR CRACKS CAUSED BY THERMAL STRESS.

ROADWORKS #306 RUBBER SEALANT IS RECOMMENDED FOR CRACKS CAUSED BY THERMAL STRESS. ROADWORKS #306 RUBBER SEALANT IS RECOMMENDED FOR CRACKS CAUSED BY THERMAL STRESS.

ROADWORKS #306 RUBBER SEALANT IS RECOMMENDED FOR CRACKS CAUSED BY THERMAL STRESS.

Cost Effectiveness

The U.S. Department of Transportation recommends rubberized crack sealing as a cost effective way to prolong the life of asphalt roadways/parking lots. For example, on average it costs five dollars to seal a 10-ft crack that is a 1/2" wide and 1/2" deep. If this same crack is left unsealed, water will penetrate and erode the sub-base, causing the surrounding asphalt to fail. This failure is called "Alligatoring". Depending on the size of the job, removing and replacing the deteriorated asphalt around the 10-ft crack costs $50 to $80.

In addition there are other intangible costs to cities or businesses, such as down time due to rehabilitation projects. There are additional costs assessed from poor image, which contributes to negative customer perceptions.

Note: According to the federal Strategic Highway Research Program (SHRP), every $1.00 spent on crack sealing, saves $4.00 in rehabilitation cost.

Material Types

All RW asphalt-type sealants are high-quality, fast curing, and will not track. ROAD WORKS, INC. stands behind all its RW sealants.

RW 304:

A premium low-modulus hot applied sealant, designed to remain pliable in cold climate. It is recommended for cold climate asphalt cracks and concrete joints that have less then 75% expansion and contraction characteristics.

RW 306:

A highly modified crack and joint sealant ideally suited for use on California roadways. RW 306 is recommended for use in severe, high-temperature climates. It is preferred by government agencies where a fast-curing, yet PLIABLE, crack sealant is required.

RW 308:

A firm rubberized material designed for parking lots with high pedestrian traffic. It is stiff yet maintains flexibility. Ideally suited for schools and shopping malls.

Other Types of Material:

- Jet Fuel Resistant

- Diesel Fuel Resistant

- Concrete Joint Sealants

Sealing Process

Cleaning:

Cracks are cleaned of all dirt, sand and debris using no less than a 185 cfm compressor at 110 psi. This will facilitate adhesion of rubberized material to the asphalt. All vegetation must be removed prior to application of material. It is recommended that a weed steril and be applied one week before removal to prevent vegetation re-growth.

Heat Lance:

All moisture must be removed from cracks to allow proper adhesion of rubberized material. A specialized hot air head lance is required for this purpose. The heat lance accompanied by a 185 cfm compressor produces an air stream velocity of 3,000 ft/sec. and an air temperature of 33,000 degrees fahrenheit.

Grinding:

Grinding provides for better adhesion of rubberized material to the asphalt crack's side wall. It also creates a reservoir for rubberized sealants. This reservoir of material will last longer and make for a better quality seal. Cracks 1/8" to 3/8" should be ground to a minimum of 1/2" wide by 1/2" deep.

Material Application:

RW rubberized sealants should be applied in prepared cracks at a temperature of approximately 380 degrees Fahrenheit.

Considerations

On occasion, cracks may be found to have other types of deficiencies. In particular, crack edges may exhibit vertical distress, such as cupping, lipping, or faulting, and/or may undergo significant vertical deflections or movements under traffic loading. Such deficiencies can add significantly to overall pavement roughness and deterioration over time.

Normal repair alternatives, such as patching and/or milling, are appropriate for correcting these deficiencies. However, if the amount of vertical deflection and the severity of the distress (lipping especially) are not too high, a temporary fix with crack treatment may be adequate.

Message us to inquire about our services or if you want to learn more.